PostNL – Planning inter transports and loading trucks #SWI2022

Apart from mail delivery, PostNL’s most important service is to transport parcels ordered at web shops to consumers. This service is provided at an enormous speed and accuracy (99% within 24 hours) and at incredibly high volumes (> 106 parcels per day). As a consequence, highly efficient business processes are required to maintain this service in a cost effective way. Moreover, PostNL is constantly reinventing its logistic organization to keep up with the enormous increase of parcel volumes and the ever changing preferences of consumers.

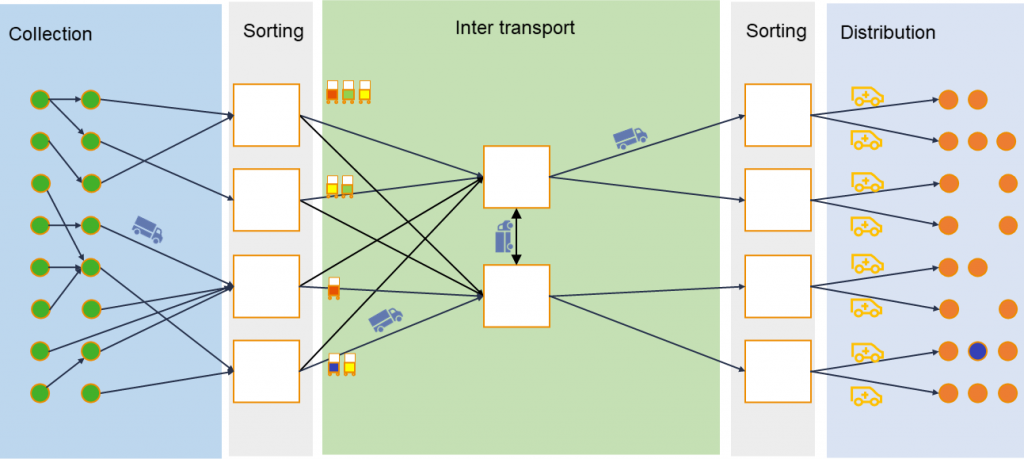

Different phases of the PostNL parcel process

The PostNL process for transporting parcels from web shops to consumers is subdivided into separate processes that can be studied and optimized more or less independently: collection, first sorting (to level of rough destination area), inter transport (cross docking), second sorting (to consumer addresses) and distribution from second sorting centre to consumer. The problem we wish to address in the Study Group is focused on the inter transport as shown in the figure.

At the first sorting process, parcels are coarsely sorted using huge sorting devices and placed in trolleys for transport to their destination distribution centres. During this process distinction is made between different due times, corresponding to different shifts in the second sorting process. In this way, each sorting centre sorts parcels into about 250 distribution centre/shift combinations. The main question of the inter transport process is to plan trucks driving from first sorting centres to distribution centres, possibly via intermediate cross-docks, in such a way that each trolley arrives in time for its shift at the least possible costs.

Given the trolley production time lines, the general inter transport problem consists of three elements:

- Devise a transport scheme that enables the transports of all trolleys to their destinations at the lowest possible costs.

- Given this transport scheme, devise a set of loading rules that prescribe which trolley should be loaded onto which truck, accounting for the maximum capacity of 48 trolleys per truck.

- The costs of the transport scheme are largely determined by the extent by which the individual transport orders can by combined to efficient trips, i.e. sequences of transport orders that are carried out by one driver. For simplicity we may assume a fixed kilometre price for the transport scheme, but add some constraints in the transport scheme to facilitate combinability into trips.

Expected results

The main focus of our problem is on points 1. and 2. above. At the end of the workshop we hope to have gained more insight into the possible mathematical models and available solution methods to address the inter transport problem efficiently and robustly. In addition, we would like to have more insight into the trade-off between the cost of unfeasible solutions (where only part of the trolleys arrive in time) and the cost of the transport scheme.