Hobaho – Optimal Use of in Vitro Techniques in Dutch Bulb Industry #SWI2018

Introduction

Dümmen Orange represents a legacy of floricultural excellence for more than a century in the making, providing the largest selection of superior flowers and plants on earth. Recently, Dümmen Orange acquired companies specialized in flowers from bulbs and tubers. The Dutch bulb industry distinguishes itself from the rest of the flower industry in that the process needs many years, and that innovation lags behind. These flowers are all types of bulbs, tulips, hyacinth, narcissus, and others. In the tubers, we breed zantedeschia and gladiolus

The bulb market is supply-driven instead of demand-driven due to the availability of the product based on natural growth. Innovations to increase the speed of the process are limited accepted by the industry. Dümmen Orange intends to develop methods and products that meet current market standards.

This means that process of product development and supply needs to speed up. This needs to be done by the implementation of methods that already are available, and with the development of new methods that can speed up the method. Here, we need to be able to make solid decisions in investments versus returns. Gain in years versus input.

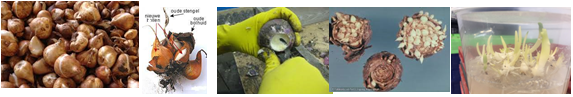

In product development (breeding for new varieties), we select first the flower that comes from one seed for its beauty. The next step is to multiply the selected progeny and perform tests on a set of 50 bulbs or tubers. The third step is to multiply to commercial numbers for sales, depending on the crop around 50,000 bulbs or tubers.

In this process, we have choices in means of multiplication. The natural way of multiplication, outside in the field (in vivo), takes 15 to 25 years before we reach commercial numbers of bulbs. For example, the multiplication factor is in tulip 2.5 bulb/bulb/year. In Zantedeschia, we can part the tuber into 85 new parts, but they need 2 years to come to adults. Through tissue culture (in vitro) the multiplication factor is much higher. The cycle itself adds another year to the process because we need an additional year to come to adults, they need to reach the appropriate size for blooming.

Problem

Tissue culture yield higher numbers but is more costly than growing outside. The difference in multiplication factor and the costs differ per crop, also the effect on the length of the process. Even within a crop, we see differences in effect on different varieties. So we need to define optimal strategies taking effect and costs into consideration.

Wish

To have a theoretical model in which we can adjust variables such that we can weigh the gain in years versus the costs.

Questions we have: In which stadium is the application of tissue culture (TC) the most effective, which number of TC we should request from our supplier, how much money we can spend to improve the TC methods such that time is even more reduced and have returns of investment, or research to reduce the costs of TC.

A model with variables:

- Multiplication factor in vitro versus in vivo; to adjust for the different crops and the stage of the application

- Growth years from the start of multiplication to product (= bulb ready to bloom)

- Costs in vitroversus in vivo (per crop are technical differences, but also in market size)

- Returns: time reduction, Price of the product, Losses of the product

Options to be studied:

- ROI TC versus scooping in hyacinth in step 2 or step 3, how many bulbs

- ROI investing in research to reduce growth years in hyacinth and calla

- ROI investing in research to reduce costs in hyacinth

- ROI Tulip in research TC