Vanderlande – Optimizing Warehouse Operations #SWI2020

Vanderlande is the global market leader for value-added logistic process automation at airports, and in the parcel market. The company is also a leading supplier of process automation solutions for warehouses.

More than 45 million parcels are sorted by its systems every day, which have been installed for the world’s leading parcel companies. In addition, many of the largest global e-commerce players and distribution firms have confidence in Vanderlande’s efficient and reliable solutions.

The company focuses on the optimization of its customers’ business processes and competitive positions. Through close cooperation, it strives for the improvement of their operational activities and the expansion of their logistical achievements. Vanderlande’s extensive portfolio of integrated solutions – innovative systems, intelligent software, and life-cycle services – results in the realization of fast, reliable, and efficient automation technology.

The challenge

The need to invest in automated and smart picking logistic solutions continues to gather pace, driven by the continued expansion of the e-commerce market. Consumers expect easy access to a diverse range of products and the high availability of items.

As a result, e-commerce and omnichannel distribution centers are pressured to cope with strict lead times, changing order profiles, and an expanding number of SKUs (Stock Keeping Unit). These demands can cause warehouse operations to reach their limit much sooner than expected.

To keep pace with such a rapidly evolving market, scalable solutions are vital. As part of our next generation of scalable solutions – evolutions – Vanderlande offers different intelligent innovative systems and life-cycle services.

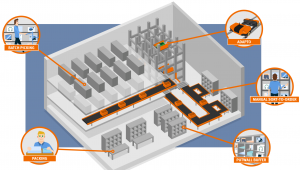

One of Vanderlande’s evolutions is LEANPICK, designed for distribution centers that are aiming to take the first steps toward automating their order fulfillment processes. It is a person-to-goods system, in which orders are picked manually via mini-batches. A mini-batch is a set of approximately 50 orders and 150 items. This batch is manually sorted to orders via a putwall. LEANPICK has a high storage density compared to other manual picking operations because SKUs are stored in a variety of locations in so-called ‘chaotic storage’.

The problem of assigning SKUs to locations (so-called slotting) and creating batches is not new. These problems are very typical for any warehouse and they could be solved using different approaches.

As an initial step Vanderlande developed a basic algorithm for SKU slotting and mini-batch creation. However, because of several assumptions and simplifications that have been made, one could quickly see the shortcomings of such an approach: it does not necessarily lead to the most optimal result.

The current slotting algorithm assigns SKUs to zones (and within a zone to aisles and sections) in a random fashion. The number of zones, aisles, and sections are the parameters. There are many combinations possible when assigning SKUs and for practical reasons, we consider just a few combinations.

The current algorithm for determining mini-batches starts with a certain order and then tries to find orders that could be fulfilled visiting the same zones. This process continues until a mini-batch is full or no candidates can be found. In the first scenario, we continue with the next order to process. In the second scenario, we need to add an additional zone to the mini-batch. During a single mini-batch creation we assume that an SKU is always in stock. However, in a real-life scenario, one would assign this zone in a smarter way, e.g. by taking stock into account, and by optimizing the workload per zone.

In order to advise our customers on how to organize the picking area, we need to explore different ways to allocate SKUs and compute corresponding metrics. Current metrics focus on work-load distribution over zones, without taking the actual walking distance into account.

An example of an outcome produced by our current mini-batch algorithm is visualized in Figure 2. Usually, operators are assigned to zones to collect pick-batches (part of a mini-batch from that zone). It is generally desired to have a maximum number of SKUs per pick-batch (determined by a maximum tote fill rate), balanced work for operators, and a few operators as possible.

Vanderlande is aiming to explore other solutions to the mini-batch creation problem. We challenge you to develop an intelligent, optimized routing solution for mini-batch picking, which outperforms our current approach. In particular (in order of priority):

- Develop a solution (using mathematical optimization) for mini-batch creation that offers more optimal solutions than the current approach. The input, in this case, is the orders and zones configuration, which is determined by the slotting algorithm.

- Incorporate actual SKU positions within zones in the algorithm and metrics, to make mini-batch creation more accurate.

Information regarding SKU distribution, order profiles, order flow, and layout constraints will be provided.

Figure 1: LEAN PICK market-leading concept

Figure 2: Visualization of work-load over zones (ignoring aisles and sections). On the vertical axis, we see zone id’s and on the horizontal mini-batch id’s. One column shows a mini-batch, indicating the zones that need to be visited and the number of SKUs that need to be picked up in that zone. One row shows work-load per zone.